Injection molding of thermoset SMC and BMC components

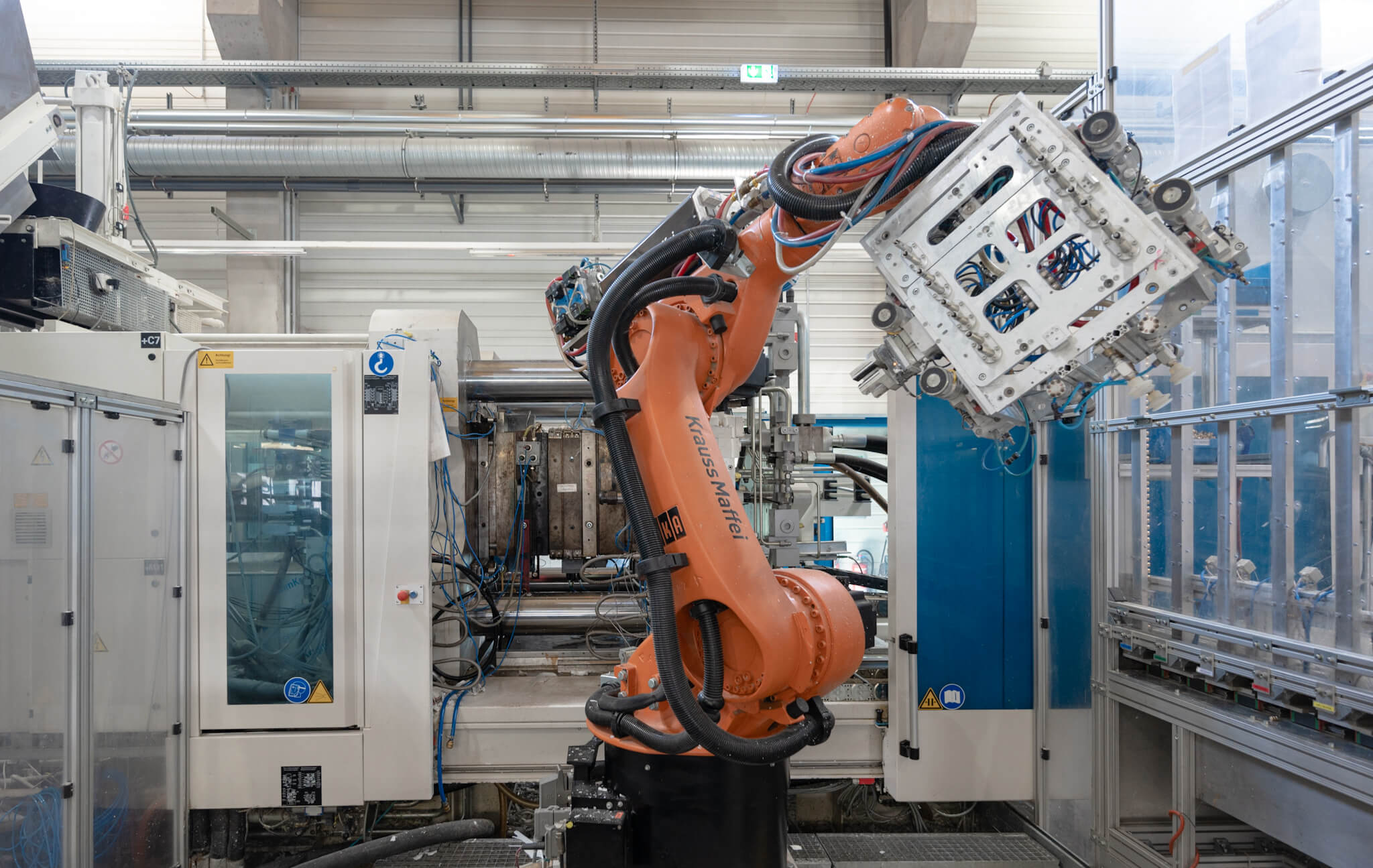

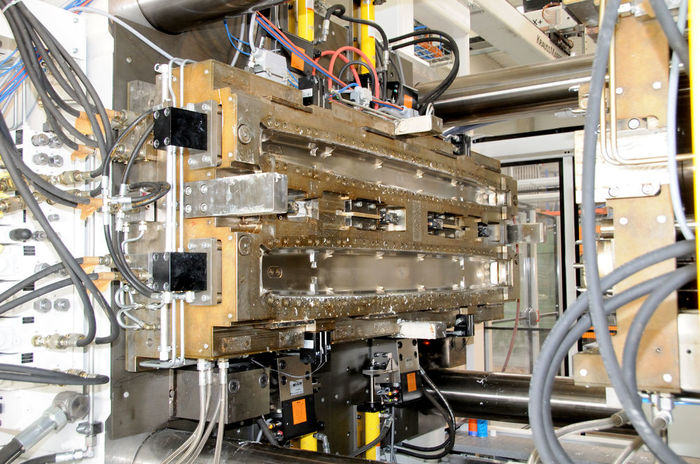

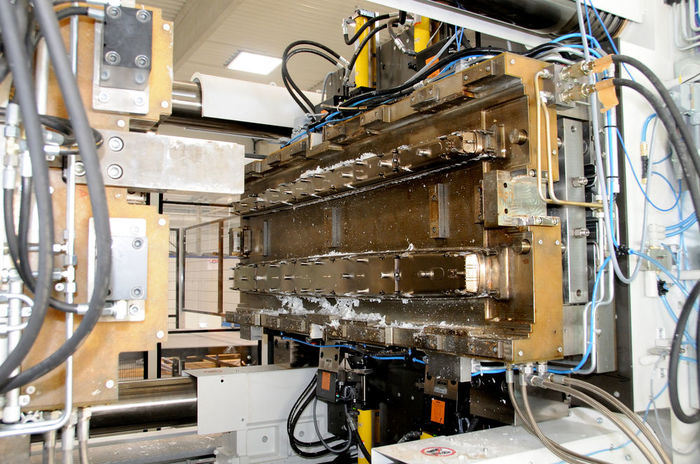

In the injection molding of fiber-reinforced thermosets, both BMC molding compounds (Bulk Molding Compound) with fiber lengths of up to 25 mm and injection-moldable SMC (Sheet Molding Compound) with fibers up to 30 mm long are processed. The semi-finished products are prepared in a temperature-controlled plasticizing screw and injected under high pressure into the closed and heated mold. Here, the material crosslinks and hardens. Typical injection molded parts are molded parts with pronounced structures and many openings. The highest surface qualities can also be achieved.

With our machinery, we can manufacture products using the injection compression molding process in addition to classic injection molded parts. This special process is particularly suitable for large-area, thin-walled molded parts with high surface qualities. In injection-compression molding, the liquefied BMC is injected into a mold that is not completely closed. The mold is not completely closed until after complete injection. This production variant has a positive influence on fiber alignment.

Very short cycle times can be achieved in the injection compression molding process. The significantly lower injection and cavity pressure compared to the classic injection molding process allow the use of economically favorable molds and machines. In addition, the same molding compounds can be used in injection compression molding as in injection molding.

© Mitras Composites Systems GmbH, Bahnhofstraße 32, 01471 Radeburg

Source: https://en.mitras-composites.com/Injection_molding