injection moulding

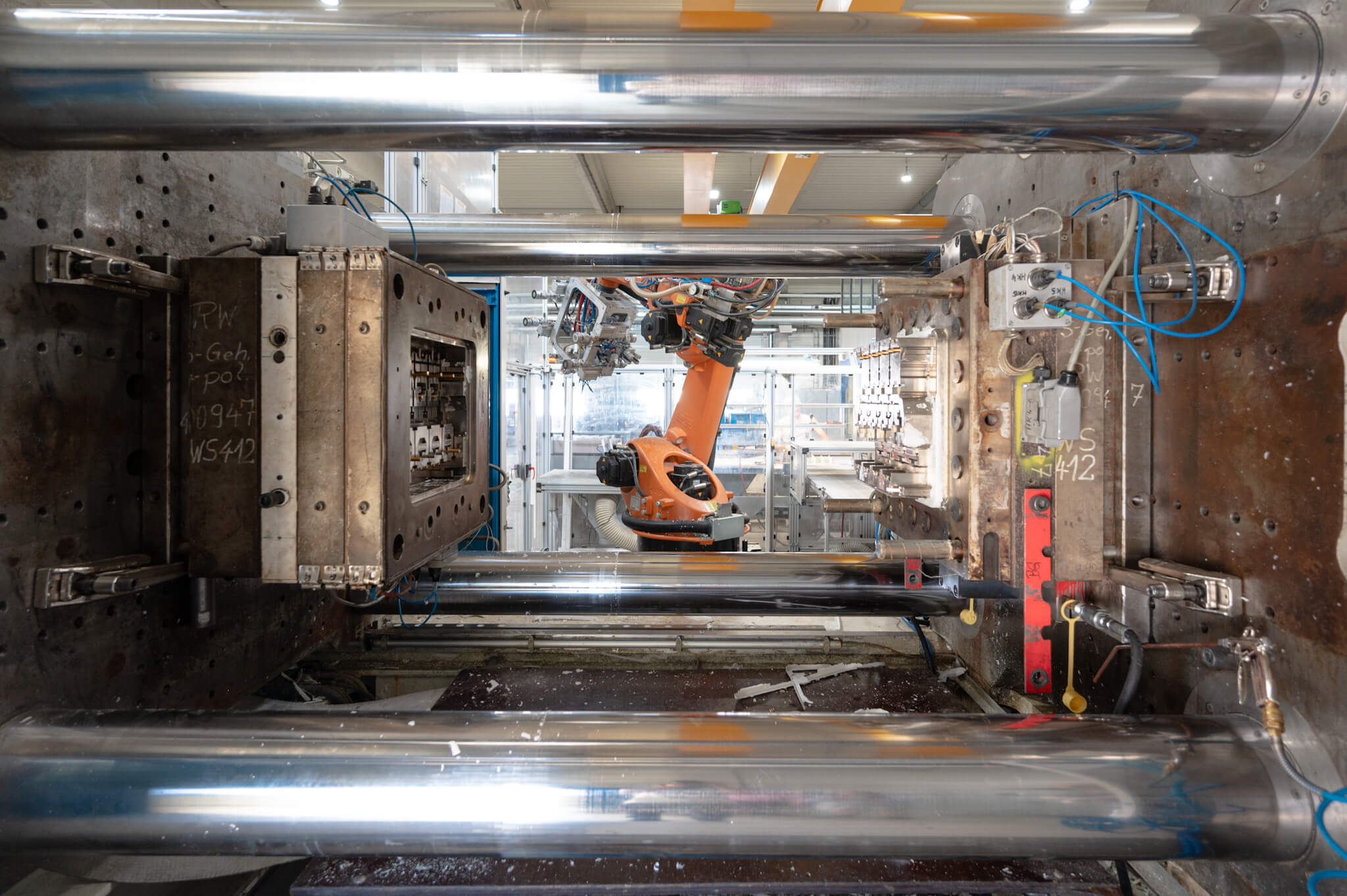

For the production of fiber-reinforced thermoset components, we can also draw on our pool of injection molding machines with different sizes and properties.

Our injection molding machines are equipped with state-of-the-art control systems that allow clamping forces of up to 13,000 KN and a maximum component weight of 6.2 kg.

With our injection molding machines, we offer you all the requirements for precise process control and short cycle times. Both injection molding and compression molding are preferably used for large quantities. Here, complex geometries can be reproduced. Press molds (tools) made of high-strength steel are necessary for this.

Our goal are lean processes. That is why our production is geared to finishing your component on the line using injection molding. The integration of metal inserts is optimally carried out in the pressing process. Likewise, downstream value-adding activities such as deburring of the component or the insertion of holes are also shifted to the place of action (to the injection molding plant).

The injection molding process allows comparatively simple use of automated auxiliaries, which are already economically viable for medium quantities.

At the same time, the quality of your parts is not neglected. A shift-accompanying QA watches over the defined requirements of your parts around the clock.

Have we awakened your interest? We would be happy to discuss your current or potential SMC or BMC component with you.

© Mitras Composites Systems GmbH, Bahnhofstraße 32, 01471 Radeburg

Source: https://en.mitras-composites.com/injection_moulding